Liquid Filling

Liquid Filling

Max. Capacity 30kg

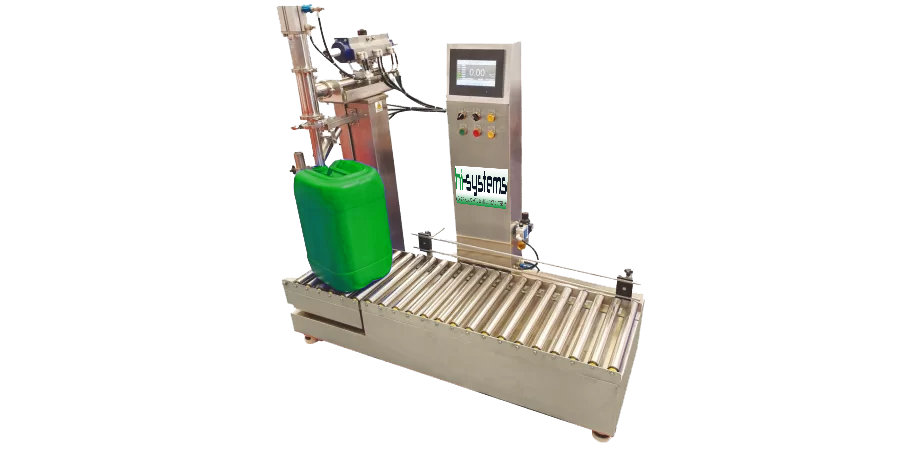

Hi Systems liquid filling systems are ideally suited for deployment in food and chemical production facilities, offering precision filling solutions for a variety of container types, including cans, drums, and barrels. These systems automate the filling process, ensuring each container is filled with exact precision to maintain consistency and reduce waste.

The systems are capable of high-speed filling operations, utilizing a dual-stage approach for fast and slow filling, which optimizes accuracy and minimizes spillage.

For environments dealing with hazardous materials, Hi Systems provides ExProof options to ensure safety and compliance with industry regulations.

Additionally, the systems are versatile enough to handle both Net and Gross filling methods, accommodating different industry standards and requirements.

Applications

Hi Systems liquid filling systems are tailored for extensive use within both the food and chemical industries, where precision and safety are paramount. These systems streamline operations by ensuring accurate and efficient dispensing of liquids into various container types, such as bottles, jars, and large storage tanks.

In food production facilities, these systems handle everything from viscous syrups to water-thin beverages, maintaining the integrity and quality of food products throughout the filling process. This is crucial for meeting health and safety standards and ensuring consumer satisfaction.

In the realm of chemical manufacturing, the liquid filling systems are designed to manage hazardous and volatile substances with utmost precision, thereby preventing contamination and ensuring safe handling practices are upheld.