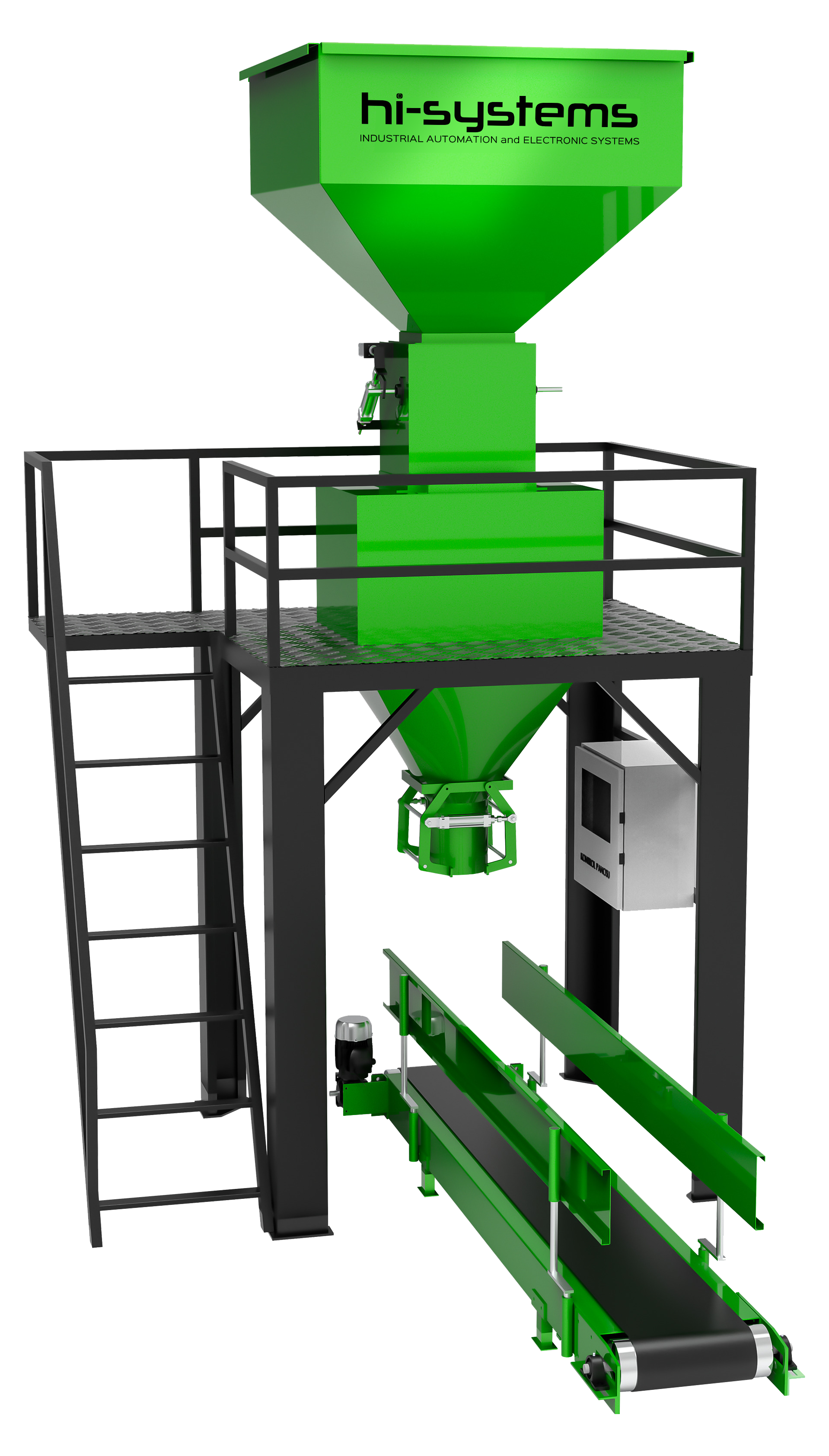

Single Flap Bagging Machine

Single Flap Bagging Machine

25-50kg

The Hi Systems 25-50kg single flap bagging machine is tailored for efficient, high-volume packaging of diverse materials such as grains, seeds, and fertilizers, along with other granular or powdered substances. This machine boasts a capacity to accommodate bags from 25 to 50 kilograms, managing up to 440 bags per hour, showcasing its capability to handle varying product demands effectively.

Engineered with state-of-the-art technology, the machine features both semi-automatic and fully automatic modes, complemented by a user-friendly touch-screen control panel. This panel enables precise control over bag weight, fill rates, and various operational settings, enhancing overall productivity and accuracy.

The packaging operation initiates with the seamless loading of bags onto the conveyor, where products are efficiently funneled into bags via dual spouts, significantly speeding up the bagging process and ensuring consistency.

The design emphasizes precision with an error margin maintained at less than ± 50 – 100 grams, suitable for meticulous handling of powders, pellets, and other granular inputs using advanced gravity or mechanical feeding mechanisms.

Safety is prioritized with robust sensors, alarms, and emergency stop features, all integrated to foster a safe working environment and mitigate any potential risks.

Maintenance is streamlined through thoughtfully designed components that are easily accessible, minimizing downtime and simplifying the maintenance and cleaning processes.

Optional enhancements such as compressors, bag sewing machines, and nylon pasting capabilities are also available, expanding the machine’s versatility and application in various industrial settings.

Applications

In industries where precise bagging is essential, Hi Systems bagging machines are pivotal. Their application in the agriculture sector for bagging commodities like flour and animal feed ensures operational efficiency and measurement accuracy.

These machines also play a significant role in the chemical industry, where they handle the filling of chemical products, particularly those in powdered form, necessitating rigorous control measures.

Within the food processing sector, their capability to package various food products in different states—from powders to liquids—demonstrates their flexibility and adherence to safety standards.

The construction materials industry relies on these machines for the effective bagging of loose materials such as gravel, benefiting from their robust construction and precision.