Wheel Loader Weighing

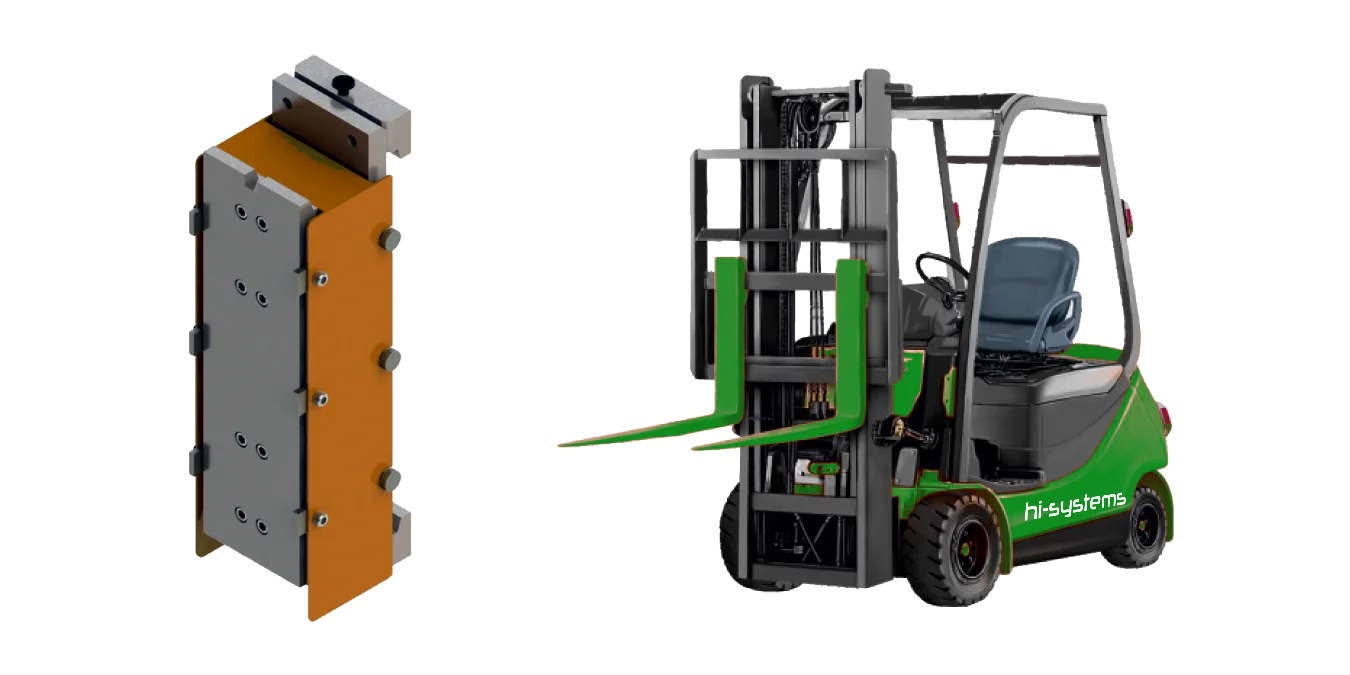

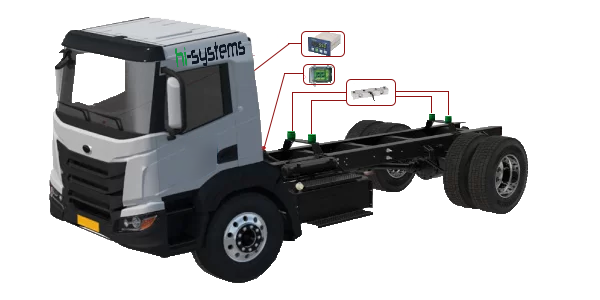

As the lift-arm of a wheel loader ascends to a predetermined height, a position sensor activates the weighing process.

The weighing indicator captures hydraulic pressure signals from both the lower and upper oil chambers of the arm-lifting hydraulic cylinder.

These signals are then processed and compensated to calculate the precise weight of the current bucket load.

This weight is automatically aggregated into the total loading weight, streamlining the process for the operator.

Alarm messages provide real-time feedback, enabling the operator to verify the validity of each bucket's load.

Additionally, adjustments based on negative deviations ensure that the last bucket's load weight is accurately recorded.

This system significantly enhances operational efficiency by allowing for real-time overload control, which is particularly beneficial for optimizing the workflow of truck drivers.

The system also features a specialized Anti-vibration Digital Filtering Algorithm, ensuring precise and stable weighing with rapid response times, alongside an Acceleration Compensation Algorithm that adjusts for movement during operations.

Its robust EMC design provides high resistance to industrial interference, ensuring reliable performance even in challenging environments.

Overall, this system offers an optimal balance of price and performance, making it an excellent choice for industrial weighing applications.